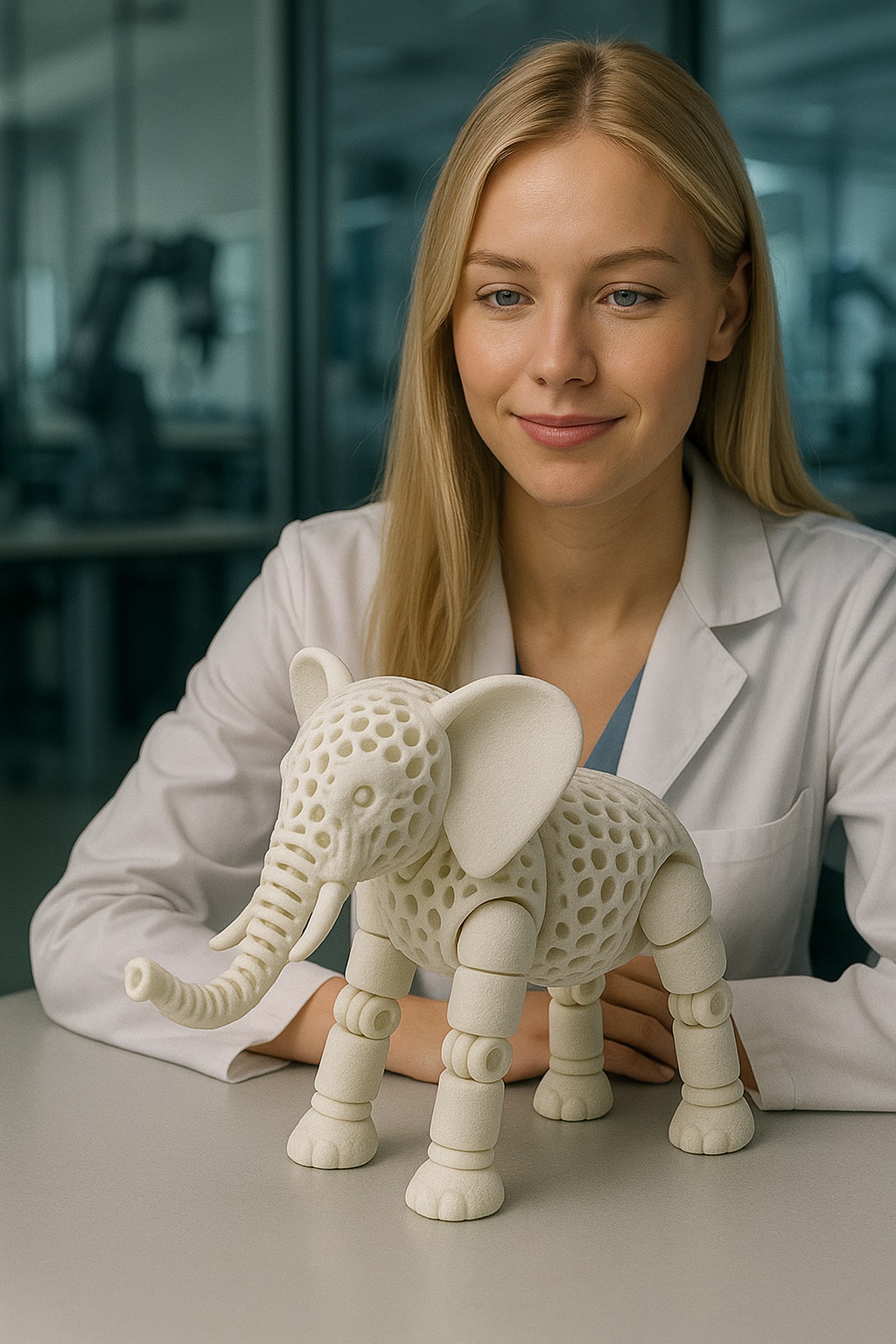

Revolutionizing Robotics: 3D-Printed Robot Elephant Mirrors Muscle and Bone Using a Single Material

Scientists at EPFL university in Switzerland have pioneered a revolutionary 3D printing breakthrough with the potential to transform the field of robotics. The team, led by Josie Hughes, has developed a programmable lattice structure capable of mimicking biological tissues, ranging from flexible muscle to rigid bone, using a single foam material.

The team demonstrated their innovative approach with a charming robot elephant. This elephant can grasp flowers with its trunk and even bowl strikes. The robot features a soft, flexible trunk capable of twisting, bending, and rotating, while maintaining rigid joints in its hips, knees, and feet—mirroring the anatomy of a real elephant.

“We used our programmable lattice technique to build a musculoskeletal-inspired elephant robot,” said postdoctoral researcher Qinghua Guan. “This shows that our method offers a scalable solution for designing unprecedentedly lightweight, adaptable robots.”

The breakthrough lies in the programmable foam cells that can assume over one million different configurations. By blending two main cell types—body-centered cubic and X-cube—researchers can create infinite geometric variations with continuously variable stiffness properties.

Published in Science Advances, this technology opens up possibilities for robots operating in fluid environments, search and rescue operations, and precision manufacturing. The foam structure’s honeycomb-like strength-to-weight ratio could enable ultra-lightweight robots while accommodating sensors and waterproofing.